Using induction heating has following advantage and feature.

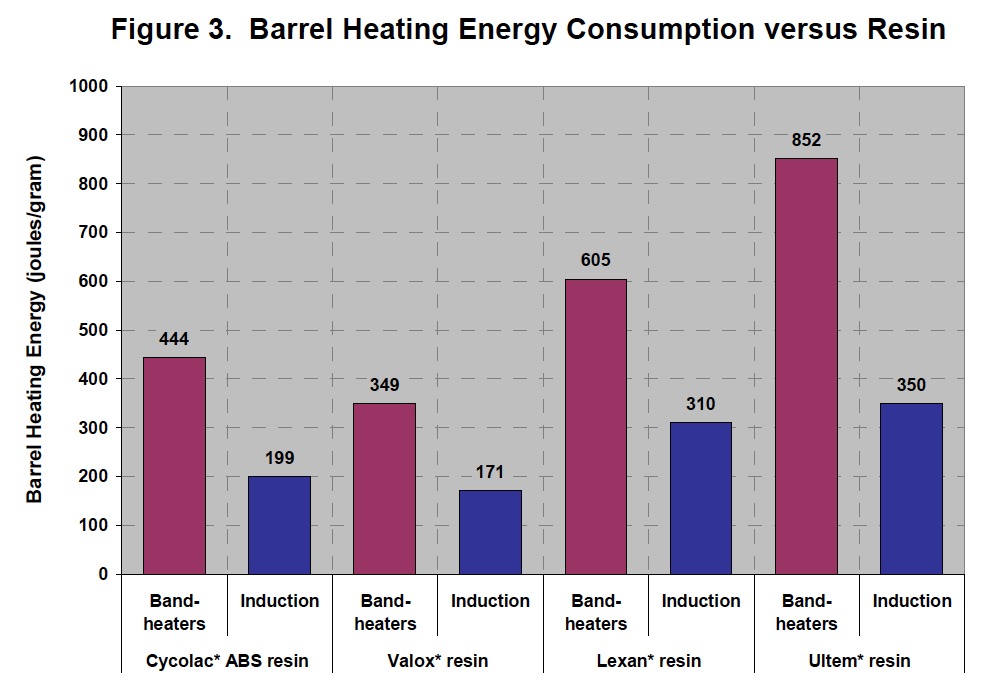

It can save 30%-80% power energy than using Resistance Wire Heating. Reduce production costs and increase competitiveness in your product

Less CO2 emissions than using coal burning heating and Increase energy efficiency, reduce waste and loss.

High Efficient, non-polluting heating

Optional function for temperature controller by K type temperature probe into Extruder barrel. also could have digital connect with PLC and other intelligent control system Such as Modbus RS 485 and SSR Control

|

Model |

Input Voltage |

Input Current |

Cross-section Cable/Output Cable Meter length/Inductance Value |

Dimension |

Net Weight |

Application |

|

SC-2500W |

220V AC Single phase |

11A |

4mm square/ 20 Meters /100-150uh |

212*135*120mm |

2.1 Kg |

Plastic Injection, Small Plastic Extruder, Shrink and Fitting |

|

SC-3000W |

220V AC Single phase |

13.5A |

6mm Square/ 15 Meters/80uh |

212*135*120mm |

2.1 Kg |

|

|

SC-3500W |

220V AC Single phase |

16A |

6mm Squarer/17 Meters/100 uh |

295*165*140mm |

4.55 Kg |

Hot Water, Plastic extruder, Oil Pipe Heating |

|

SC-5000W |

220V AC Single phase |

22A |

10mm Square/13-15 Meters /60-80uh |

295*165*140mm |

4.55 Kg |

|

|

SC-5KW |

3 phases 380V AC |

7.5A |

6mm Square/45-55Meters/250-300 uh |

360*185*180mm |

7.3Kg |

Medicine/Chemical/petroleum heat/Plastic Extruder/Hot Water |

|

SC-8000W |

220V AC Single phase |

36A |

20-25mm Square/8-10 Meters/50-55uh |

360*185*180mm |

7.3Kg |

|

|

SC-8KW |

3 phases 380V AC |

12A |

10mm Square/43 Meters/200-250uh |

360*185*180mm |

7.3Kg |

|

|

SC-10KW |

3 phases 380V AC |

15A |

10mm Square/35 Meters/150-180uh |

360*185*180mm |

7.3Kg |

|

|

SC-15KW |

3 phases 380V AC |

22A |

16mm Square/30 Meters/110-140uh |

360*185*180mm |

7.3Kg |

|

|

SC-20KW |

3 phases 380V AC |

30A |

16mm Square/50-60 Meters/200-300uh |

290*250*240mm |

12.35Kg |

Pharmaceutical and chemical industry, construction, plastics |

|

SC-30KW |

3 phases 380V AC |

45A |

20mm Square/45-50 Meters/180-200 uh |

450*260*245mm |

16.2Kg |

Pharmaceutical and chemical industry, construction, plastics,Heating stove, energy, oil pipeline |

|

SC-40KW |

3 phases 380V AC |

60A |

25mm Square/45-50 Meters/150-200 uh |

510*325*290mm |

22.85 Kg |

Pharmaceutical and chemical industry, construction, plastics,Heating stove, energy, oil pipeline, Reactor |

|

SC-50KW |

3 phases 380V AC |

75A |

35mm Square/38-40Meters/120-140uh |

510*325*290mm |

22.85 Kg |

|

|

SC-60KW |

3 phases 380V AC |

90A |

35mm Square or Double 35mm Square /35-40Meters/110-120uh |

510*325*290mm |

22.85 Kg |

|

|

SC-70KW |

3 phases 380V AC |

100A |

50mm Square Double 35mm Square /35-40Meters/110-120uh |

572*370*315mm |

32.4 Kg |

Pharmaceutical and chemical industry, construction, Reactor |

|

SC-80KW |

3 phases 380V AC |

120A |

50mm Square Double 35mm Square /30-35Meters/90-110uh |

572*370*315mm |

32.4 Kg |

|

|

SC-90KW |

3 phases 380V AC |

135A |

Double 35mm Square/30-35 Meters/80-100uh |

635*445*315mm |

42 kg |

Heating stove, chemical industry, boiler |

|

SC-100KW |

3 phases 380V AC |

150A |

70mm Square or Double 35mm Square/30-35 Meters/80-100 uh |

635*445*315mm |

55 Kg |

Electromagnetic induction heater for plastic extruder, which is new type heater for replace old type of resistance wire heating and ceramic heater on PP, PE and etc plastic. The High frequency induction heat generators with cable coil wrap up is innovation idea heating solution on advantage of electric power energy saving.

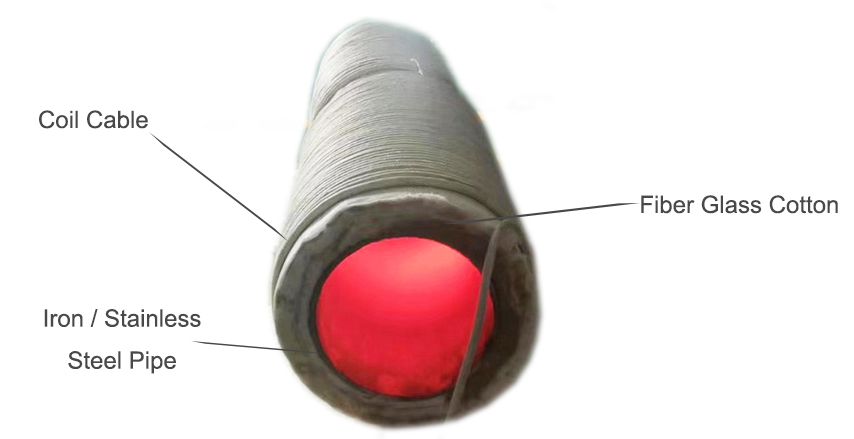

Basic Accessories Introduction

Copper Coil Cable Anti Temperature 500 Degree C. This part for generate the electromagnetic field to the workpiece and heated.

Fiber Glass Cotton usually keep thickness 20mm between coil cable and workpiece for keep thermal and higher effecient for induction heating purpose.

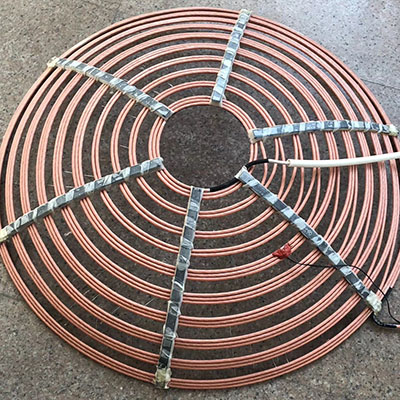

THE HEATING ELEMENT COIL CABLE CAN BE DIFFERENT SHAPE FOR DIFFERENT WORKPIECE NEED HEATED

Advantages Feature

1) Induction Heating Energy Saving 30%-80% than Resistance wire heating.

2) Modbus RTU RS 485 Communication Interface. Remote control optional.

3) Digital Programmable Technology

4) Industrial-grade AVR all-digital high-speed processor

5) Dual-core half-bridge/full-bridge drive structure

6) Optocoupler drive technology

7) Soft Start/stop Technology.

8) Stepless power regulation 20%-100%

9) Fast heating rate

10) Infineon frequency conversion technology, strong anti-interference ability

11) Energy efficiency up to 98%

12) Self-adaptive coil, large inductance range

13) Generally, application For Plastic Industry injection, Plastic extrusion, Hot water, Hotel, School, Farm, Boiler, Oil pipe, Mold heating,Die preheating and Tea drought etc